Mining Industry

Mining Industry

- Ngành sản xuất Nhiều nhà máy sản xuất sử dụng máy nén khí di động để cung cấp khí nén cần thiết cho dây chuyền sản xuất và các quy trình chế biến.

Understanding Drainage Pumps A Comprehensive Overview

디젤 공기 압축기란?

At its core, submarine hammer drilling employs a powerful hammer mechanism to drive a drill bit into the seabed. The system utilizes both air and water pressure to deliver repeated impacts on the drill bit, which enables it to break through hard rock formations or sediments that might hinder installation efforts for marine infrastructure. The design of the hammer ensures that the energy is efficiently transmitted to the drill bit, allowing it to operate at significant depths.

Understanding Drainage Pumps A Comprehensive Overview

Что такое дизельный воздушный компрессор?

The mud pump market is populated by various suppliers, ranging from niche manufacturers to global leaders. Companies like Gardner Denver, Halliburton, and Schlumberger are well-known for their extensive product offerings and technological expertise. Additionally, there are many regional suppliers that cater specifically to local markets, offering competitive prices and localized support.

Submarine hammer drilling, often referred to as underwater percussion drilling, is an advanced technique utilized primarily in marine construction and resource exploration. This method combines the principles of traditional drilling with hydraulic and pneumatic operations, enabling the effective penetration of hard substrates beneath the sea floor. In this article, we will explore the processes, equipment, advantages, and applications of submarine hammer drilling.

Another significant benefit of RDP is its contribution to sustainability in construction. As a component of dry-mix formulations, it facilitates extended working times and open times, enhancing the efficiency of labor and reducing waste. Additionally, the use of RDP can allow for the partial replacement of traditional polymer additives, providing economic benefits and a reduction in the environmental impact of construction materials.

Applications

Conclusion

HPMC (Hydroxypropyl Methylcellulose) là một polymer cellulose được sử dụng phổ biến trong nhiều ngành công nghiệp, đặc biệt là trong ngành dược phẩm, thực phẩm và xây dựng. Một trong những đặc tính quan trọng của HPMC là khả năng hòa tan trong nước, điều này mang lại nhiều lợi ích khi sử dụng trong các ứng dụng khác nhau.

HPMCの供給は、原材料の調達から製造、流通までの一連のプロセスを含みます。サプライヤーは、品質管理を徹底し、高品質なHPMCを安定的に供給することが求められます。これにより、建設業者や製薬企業は、製品のパフォーマンスを確保し、顧客の信頼を得ることができます。

1. Specialty Chemical Suppliers The most straightforward way to obtain Cellosize is through specialty chemical suppliers. These companies typically offer a range of hydroxyethyl cellulose products, and they may even substitute or recommend alternatives if necessary. Websites like Sigma-Aldrich and Fisher Scientific often have a variety of chemical products, including Cellosize, available for purchase.

The selection of the appropriate HPMC viscosity grade depends on several factors, including the nature of the formulation, the desired viscosity, and the specific application requirements. For instance, a pharmaceutical product may require a specific viscosity to ensure proper drug delivery, while a cosmetic formulation might prioritize texture and stability. Manufacturers must carefully assess these parameters to achieve optimal performance in their products.

Moreover, RDP enhances the overall durability and water resistance of formulations. It creates a network of polymer particles that encapsulate the cement particles, contributing to a denser and more resilient matrix. This characteristic not only increases the durability of the end product but also improves its performance in wet conditions, making it ideal for both interior and exterior applications.

ในอุตสาหกรรมอาหาร HPMC ถูกใช้เป็นสารทำละลายและสารเพิ่มความหนืด สารนี้ช่วยปรับปรุงเนื้อสัมผัสและความคงตัวของผลิตภัณฑ์ เช่น ซอสพริก เนยถั่ว และผลิตภัณฑ์นม เพื่อให้ผู้บริโภคได้รับประสบการณ์การบริโภคที่ดีขึ้น นอกจากนี้ HPMC ยังใช้ในการผลิตผลิตภัณฑ์ที่ปราศจากกลูเตน เนื่องจากมีคุณสมบัติในการสร้างเจลที่ทำให้เนื้อขนมปังมีความเหนียวนุ่มในขณะที่ปราศจากโปรตีนที่ได้จากแป้งข้าวสาลี

HPMC, znan tudi kot hidroksipropil metilceluloza, predstavlja ključno snov v različnih industrijah, vključno z gradbeništvom, farmacijo, živilsko industrijo in kozmetiko. Njegova vsestranskost in prilagodljivost sta ga uvrstila med najbolj iskanih dodatkov na trgu. Kitajska, kot ena izmed največjih proizvajalk HPMC na svetu, igra pomembno vlogo pri zagotavljanju te pomembne kemijske spojine.

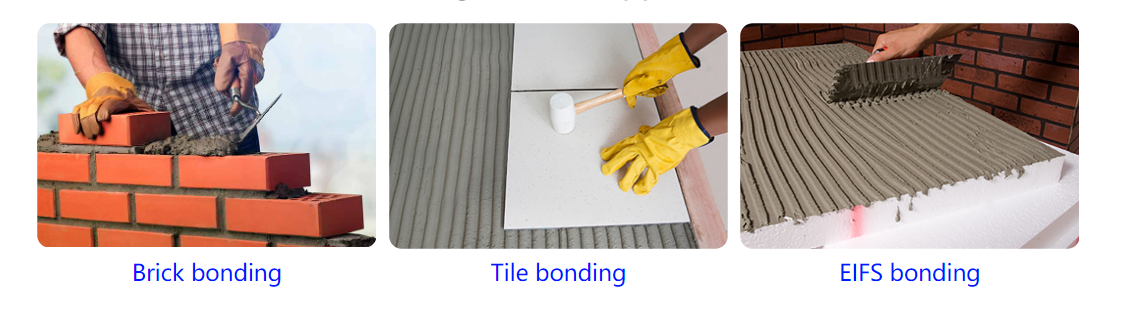

1. Construction Industry The primary application of RDPs is in the construction sector. It is widely used as an additive in tile adhesives, cementitious coatings, and renders. By improving the workability and flexibility of these materials, RDPs ensure better adhesion to various substrates, thus enhancing the longevity and performance of construction projects.

Solubility Characteristics of HPMC

Additionally, RDP is used in the formulation of textured coatings. These coatings benefit from the improved flexibility and adhesion provided by RDP polymers, which help prevent cracking and peeling over time. The result is a long-lasting finish that can withstand the rigors of weather and wear.

Applications of Hydroxyethyl Cellulose Powder

In cosmetics and personal care products, HPMC is valued for its thickening and stabilizing properties. It is commonly found in creams, lotions, and gels, where it contributes to the desired consistency and improves the product's sensory characteristics. HPMC also enhances the performance of hair care products by providing a film-forming effect, enabling better adherence and distribution of the product on hair strands.

HPMC-nin mənşəyi və istehsal prosesinin asanlığı da onun bazarını genişləndirir. HPMC, bitki selülozundan hazırlanır ki, bu da onu ekoloji cəhətdən dost və bioloji parçalanan məhsul edir. Bu səbəbdən, istehsalçılar və istehlakçılar arasında HPMC-yə artan maraq duyulur. Bununla yanaşı, HPMC-nin dünya miqyasında müntəzəm tədarük zəncirləri ilə dəstəklənməsi, qiymət stabilliyini və bazar sağlamlığını təmin edir.

Furthermore, HPMC finds applications in the cosmetics and personal care industry, where it is used as a thickening agent and emulsifier in lotions, creams, and gels. Its ability to enhance product stability and improve sensory attributes has made it a popular choice among cosmetic formulators. HPMC manufacturers are continually innovating to produce grades that cater to the evolving demands of this fast-paced industry.

Fabricantes de Polvos de Látex Redispersables Innovación y Calidad en la Industria

Environmental Considerations

Mu nthawi ya dzikhumbo la njira yatsopano mu ntchito ya zamafuta, HPMC (Hydroxypropyl Methylcellulose) ndi HEC (Hydroxyethyl Cellulose) akhala akugwiritsidwa ntchito kwambiri. Makampani a zamafuta akufuna kukhazikitsa zinthu zomwe zili ndi magwiridwe antchito abwino, ndipo HPMC ndi HEC akuti ali ndi masewera aikulu m'ndandanda wa zinthu zomwe zimalimbikitsa ntchito ya makampani a kuwala.

Die Kombination von VAEs und RNNs eröffnet interessante Möglichkeiten für innovative Anwendungen. Ein Beispiel hierfür ist die Generierung von Texten, bei der ein VAE genutzt wird, um die Struktur und die Stilistik bestehender Texte zu erlernen, während das RNN die Fähigkeit hat, sprachliche Kontinuität und Kohärenz in den generierten Texten aufrechtzuerhalten. Dadurch können realistische und zusammenhängende Texte erzeugt werden, die jedoch nicht direkt aus den ursprünglichen Trainingsdaten stammen.

- MCC (MethylCellulose Company) MCC is focused on the production of cellulose derivatives, including HPMC. Their products are utilized in multiple sectors, providing tailored solutions to meet specific customer needs.

In the pharmaceutical industry, HPMC is widely used as a binder in tablet formulations, a thickener in liquid dosages, and a stabilizer in emulsions. Its ability to control the release of active pharmaceutical ingredients makes it invaluable in controlled-release formulations. HPMC's non-ionic character also ensures minimal interactions with other excipients, enhancing the overall efficacy of the drug.

Gypsum plaster को उपयोग गर्दा HPMC ले पानीको कमीलाई कम गरेर सीधा लाभ पुर्याउँछ। पानीले एक महत्त्वपूर्ण भूमिका खेल्छ, किनकि यसले प्लास्टरलाई सुगन्धित बनाउँछ। HPMC को साथ, एक समयमा धेरै नरम र परिवर्तनशील मिक्सिङ प्राप्त गर्न सकिन्छ। यो पद्धतिले मिक्सिङको समय र पानीको खपत घटाउँछ, जसले आर्थिक लाभ ल्याउँछ।

The Role of RDP Polymer in Modern Applications

Hydroksypropylometyloceluloza znajduje zastosowanie w różnych dziedzinach. W budownictwie jest używana jako dodatek do zapraw i klejów, poprawiając ich konsystencję oraz właściwości przylegania. Dzięki swojej zdolności do zatrzymywania wody, HPMC zwiększa czas otwarty materiałów budowlanych, co pozwala na dłuższe czas pracy.

In recent years, there has been a growing focus on sustainability and environmental impact in construction materials. HPMC is non-toxic and environmentally friendly, aligning with the demand for greener alternatives in the industry. Its use in putty powders not only enhances performance but also contributes to safer working environments and sustainable building practices.

이와 같은 폴리머 파우더의 주요 장점 중 하나는 유동성을 높여서 작업성을 개선하는 것입니다. 이는 바닥재, 타일 접착제, 미장제와 같은 다양한 건축 자재의 적용 시 더욱 쉽고 빠르게 작업할 수 있도록 돕습니다. 작업자가 설치하거나 시공하는 과정에서 에너지를 절약하고, 시간 비용을 줄이는 효과를 가져옵니다.

As industries continue to evolve and demand for HPMC expands, the role of suppliers is more critical than ever. They not only provide essential raw materials but also contribute to innovation, quality assurance, and sustainability in product development. In this competitive landscape, manufacturers must prioritize building strong relationships with reputable HPMC suppliers to ensure the successful delivery of their products to end consumers. The future of HPMC products relies heavily on the capabilities and reliability of their suppliers, making them a vital part of the supply chain.

또한, HPMC Ltd는 지속 가능한 발전을 위해 환경 보호에도 힘쓰고 있습니다. 친환경 제품 개발과 탄소 배출 저감을 위한 다양한 노력을 기울이며, 사회적 책임을 다하는 기업으로 성장하고 있습니다. 이러한 노력은 HPMC Ltd가 단순한 이익을 추구하는 기업이 아니라, 사회에 긍정적인 영향을 미치는 기업임을 보여줍니다.

In de voedingsmiddelenindustrie wordt HPMC gewaardeerd om zijn verdikkende en emulgerende eigenschappen. Het kan worden aangetroffen in verschillende producten zoals sauzen, dressings en ijs. Het verbetert de textuur en stabiliteit van voedselproducten, waardoor ze aantrekkelijker en gebruiksvriendelijker worden. HPMC is ook een belangrijk ingrediënt in glutenvrije bakmixen, waar het helpt om de structuur en veerkracht van het eindproduct te verbeteren.

Properties of HPMC

In the food industry, hydroxyethyl cellulose serves as a food additive that acts as a thickener and stabilizer, ensuring the desired consistency and texture of various food products. It is commonly used in sauces, dressings, and dairy products, where it helps improve mouthfeel and stability. Furthermore, HEC is recognized for its ability to form gels, making it a popular choice in low-fat and reduced-calorie food formulations.

At its core, hydroxyethyl cellulose is produced by the reaction of cellulose with ethylene oxide, which introduces hydroxyethyl groups into the cellulose chain. This modification enhances the solubility of cellulose in water, making HEC an ideal thickening agent, film former, and stabilizer. The process of hydroxyethylation results in a polymer that retains the beneficial properties of natural cellulose while offering improved solubility and rheological properties.

The use of RDPs also extends to self-leveling compounds, where they contribute to improved workability and reduced cracking. Additionally, their presence in external wall insulation systems enhances thermal performance and weather resistance, thereby contributing to energy efficiency in buildings.

1. Purity and Specifications Not all grades of HEC are created equal. Depending on your application, you might need a specific viscosity range or purity level. Always check the technical data sheet of the product for its specifications.

Hydroxyethylcellulose (HEC) powder is a non-ionic, water-soluble polymer derived from cellulose, a natural polymer found in the cell walls of plants. This versatile compound has gained significant attention across various industries due to its unique properties and functional capabilities. As a thickening agent, binder, stabilizer, and film former, HEC powder is widely used in personal care products, pharmaceuticals, food applications, and industrial formulations.

HPMC Manufacturers A Key Player in the Pharmaceutical Industry

Moreover, HPMC has found its way into the realm of 3D printing. As a biodegradable material, it is increasingly used as a support structure in the printing of complex objects, allowing for easier removal without damaging the printed item itself.

HPMC is also utilized in the production of dry mix formulations. When mixed with water, it activates to create a reliable product that adheres well to surfaces and resists cracking and shrinkage during the drying process.

5. Flexibility and Elasticity When HPMC is used in skim coats, it imparts flexibility and elasticity to the final product. This characteristic is particularly important in environments where temperature fluctuations can cause expansion and contraction of materials. By accommodating movement, HPMC-enhanced skim coats help to prevent cracks and improve the overall resilience of the surface.

CMC is similarly valuable in cosmetic formulations, where it helps improve the viscosity and stability of products. Its ability to bind water is particularly beneficial in moisturizing formulations, contributing to the hydration of the skin.

HPMC finds applications in various sectors, proving its versatility

2. Wide Range of Products Online platforms often present a broader assortment of HPMC grades and formulations. As different applications require specific characteristics, such as viscosity and solubility, buyers can find the exact type of HPMC needed for their projects.

هیدروکسیپروپیلمتیلسلولز (HPMC) یک پلیمر طبیعی است که از سلولز به دست میآید و در صنایع مختلف به عنوان یک مواد افزودنی و مواد اولیه بسیار مورد توجه قرار گرفته است. این ترکیب به دلیل ویژگیهای منحصر به فردش، از جمله قابلیت حل شدن در آب، گرانروی بالا و خاصیت چسبندگی خوب، به عنوان یک ماده کارآمد در زمینههای مختلف شناخته شده است.

Environmental Considerations